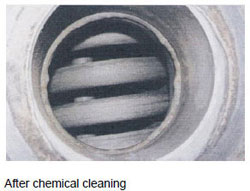

Chemical Cleaning

In today’s industrial environment, maintenance & energy cost form a large part of the operating cost. In case downtime and/or equipment design does not permit mechanical cleaning, the most cost effective solution is Chemical Cleaning.

OZEST's key is of providing quality chemical cleaning rest in the engineered selection process. We have the largest variety of solvent systems, including chelants, organic solvents, inhibitors, alkaline cleaners, emulsions, organic acid, mineral acids, and detergents from which to develop cost effective chemical cleaning processes.

Metallurgies & Others handled

- Admiralty Brass

- Copper

- Carbon steel

- Austenitic Stainless steels (300 series)

- Martensitic Stainless steels (400 series)

- Inconel

- Monel

- Titanium

- Zirconium

- Borosilicate Glass

Typical Applications:

- Boilers

- Piping

- Heat exchangers

- Evaporators

- Cooling water

- Systems & towers

- Reactor jackets

- Process vessels

Chemical Cleaning is proven, efficient & widely accepted method for removal of deposits formed in various refineries, petrochemical plants, and power generation plant equipment

There are two main types of acids used in dissolving contaminants or scales:

Minerals Acids

- Hydrochloric Acid

- Sulfamic Acid

- Nitric Acid

- Phosphoric Acid

- Sulfuric Acid

Organic Acids

- Citric Acid

- Ammoniated Citric Acid

- Oxalic Acid

- Glacial Acetic Acid

During the chemical cleaning various inhibitors are used. The inhibitors form a protective film on surface of metal in order to protect parent metal from reacting with the acid. Inhibitors do not change the rate of reaction of acid on the scale; they inhibit the metal from reacting with the acid. OZEST applies different types of inhibitors based on the acid selection.

Advantages of Chemical Cleaning:

• It can be performed on site without disassembling & moving equipment, saving enormous time, labor &

associated costs.

• It eliminates the need for physical entry of personnel thus offering a much safer

alternative.

• It conditions the process surface to reduce future fouling.

• It can handle systems which are difficult to reach by other conventional cleaning methods such as hydro jetting.

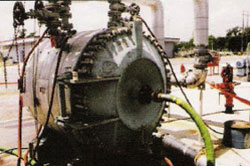

OZEST is fully equipped to handle all your chemical needs at a short notice with Circulation Pumps rated from 400-1500 GPM @ up to 150 psi; Holding Tanks from 1,000-52,000 USG capacity; Chemical resistant, Rubber and Steel hoses, on site laboratory services.

In today’s industrial environment, maintenance & energy cost form a large part of the operating cost. In case downtime and/or equipment design does not permit mechanical cleaning the most cost-effective solution is Chemical Cleaning.

OZEST’s key is of providing quality chemical cleaning rest in the engineered selection process. We have the largest variety of solvent systems, including chelants, organic solvents, inhibitors, alkaline cleaners, organic acid emulsions, mineral acids, and detergents from which to develop cost-effective chemical cleaning processes.

Typical Applications:

- Boilers

- Piping

- Heat Exchangers

- Evaporators

- Cooling Water Systems & Towers

- Reactor Jackets

- Process Vessels

Metallurgies & Others Handled

- Admiralty Brass

- Copper

- Carbon Steel

- Austenitic Stainless Steels (300 Series)

- Martensitic Stainless Steels (400 Series)

- Inconel

- Monel

- Titanium

- Zirconium

- Borosilicate Glass

OZEST is fully equipped to handle all your chemical cleaning needs at a short notice with Circulation Pumps rated from 400 – 1500 gpm @ up to 150 psi; Holding Tanks from 1,000 – 52,000-gallon capacity; Hypalon Steel Braided Hoses, On-Site Laboratory Services.

Chemical Cleaning is proven, efficient & widely accepted method for removal of deposits formed in various refineries and petrochemical plants equipment.

There are two main types of acids used in dissolving contaminants or scales:

Mineral Acids

- Hydrochloric Acid

- Sulfamic Acid

- Nitric Acid

- Phosphoric Acid

- Sulfuric Acid

Organic Acids

- Citric Acid

- Ammoniated Citric Acid

- Oxalic Acid

- Glacial Acetic Acid

During the chemical cleaning Inhibitors are used. The inhibitors form film-on-surface of metal in order to protect parent metal from possible acid attack. Inhibitors do not change the rate of reaction of acid on the scale; they inhibit the metal from reacting with the acid. Different types of inhibitors are used in the industry based on the acid selection.

Advantages of Chemical Cleaning

- It can be performed on site without disassembling & moving equipment, saving enormous time, labor & associated costs.

- It eliminates the need for physical entry of personnel thus offering a much safer alternative.

- It conditions the process surface to reduce future fouling.

- It can handle systems which are difficult to reach by other conventional cleaning methods such as hydro jetting.